Customised Enzyme Development and Manufacture

Are you looking to develop your own unique enzyme? Biocatalysts offer a flexible, unique and fully certified contract development and fermentation concept at different processing scales to a multitude of clients from diverse industries.

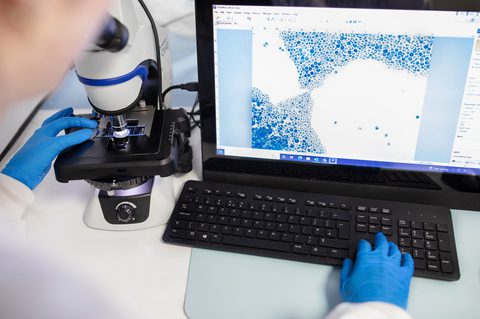

Our commercially focused approach from concept to routine manufacture of bespoke enzyme products enables us to mitigate risks by developing an enzyme process that is technically and commercially robust. We call this our “Design for Manufacture” approach. The effectiveness of our “Design for Manufacture” approach is highlighted here as the sample will be developed using techniques which are fully scalable. These projects are run by a team of qualified project managers together with PhD level molecular biologists and fermentation scientists.

We have our own Metagenomics Library that allows us to access an abundance of previously unexplored enzyme sequences. We have sourced our library from diverse environmental localities comprising acid/alkaline. hot/cold, arid, wet, saline etc. This is a unique and valuable resource for enzyme discovery that, combined with our novel bioinformatics platform, can rapidly identify panels of variants of your enzyme that we can synthesise and provide to you for testing.

Are you looking for an enzyme active at a higher than usual pH, have a certain substrate specificity in mind or require optimum activity at an extremely low temperature? Our metagenomic library could hold the answer!

Having a sample of the enzyme allows you to assess whether the enzyme does what it needs to do in your application. Typically produced from laboratory scale fermentations, this is the first step in designing a fully scalable manufacturing process for your enzyme.

This enzyme sample will be provided with an activity specification. It is also possible to develop a full activity specification if required.

The short timescale on our sample service, ultimately reduces your time to market, allowing for your unique product to be developed and begin delivering profit when you want it.

As a leading enzyme development and manufacturing company, we believe the best conditions for the process are identified using a combination of “Design of Experiment” and state of the art parallel micro-fermentation technology at 0,5L - 3L fermentation volumes. These conditions are then confirmed on a larger scale up to 70L fermentation volume.

The overall output is a fully scalable, optimised enzyme production process which is designed for routine manufacture. At the end of this stage, the enzyme is ready to be produced at commercial volumes.

This includes all the benefits of being a Biocatalysts standard enzyme product:

- Assay and specification development

- Formulation & stability

- Supply optimisation

- Regulatory support

- Kosher & Halal certification

- Full compliance & quality control

- Application support

As part of our enzyme manufacturing process the enzyme will go through an appropriate pilot scale up to 750L. We have industrial scale fermentation capacity of 2 x 10,000L and full downstream processing including spray- and freeze drying capabilities, to ensure your desired scale is achieved. The output of this stage is a product ready for market entry.

Contact an expert

Use the form below to contact a specialist about your custom enzyme requirements.