Biocatalysts’ Various Protein Production Hosts for Optimising Expression

At Biocatalysts we are able to offer highly versatile protein production hosts to address our customers’ needs and develop our own novel enzymes.

Alongside off-the-shelf enzymes, Biocatalysts Ltd offers a full enzyme discovery, scale-up, manufacture and toll-manufacturing service. To provide this service we use either bacteria or yeasts for the recombinant production of the enzyme being manufactured. Using our extensive knowledge of these production hosts gives us the capability to develop and manufacture a large range of enzymes.

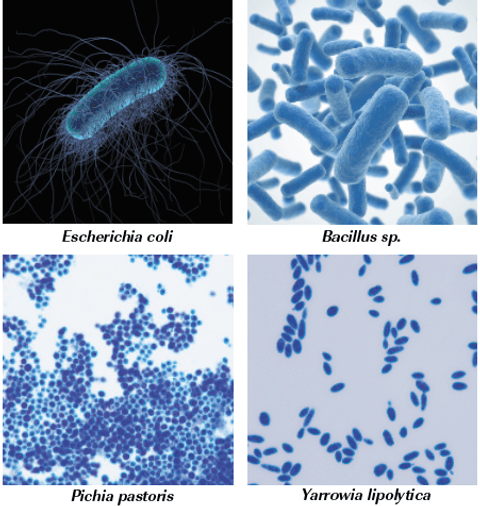

At Biocatalysts we are able to offer highly versatile protein production hosts to address our customers’ needs. We use these same strains to develop our own novel enzymes. In order to expand our offer, we have recently included in our portfolio the oleaginous yeast Yarrowia lipolytica, which expands Biocatalyst’s current production capabilities of Pichia pastoris, Bacillus sp. and the workhorse bacteria Escherichia coli. The high production yields and low complexity of the downstream process have made Y. lipolytica the ideal first organism to grow in our brand new 10m³ fermentation facility, with the aim of soon launching our first commercial enzyme produced using this strain.

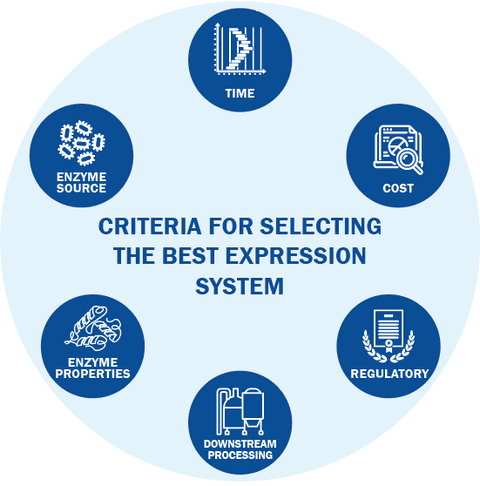

In addition to taking the customer requirements into consideration, we based the selection of the best expression host on a number of specific parameters that have been selected based on Biocatalysts’ years of experience working in the discovery, scale up and manufacture of enzymes, these are highlighted in Figure 2.

When it comes to the selection of either Y. lipolytica or P. pastoris, the attention is mainly focused on the features of the protein of interest and how these can be affected by the post-translational modification occurring in each species. The expression yields of two enzymes belonging to different classes vary significantly in the two yeasts, with a lipase and a protease-like enzymes expressed at higher levels in Y. lipolytica and P. pastoris, respectively.

At Biocatalysts we ensure that we are able to optimise all production processes, no matter which expression host is selected. Having the ability to perform the fermentation process over a range from 250mL to 18m³ scale makes it possible to efficiently optimise. Being able to approach every production process with a scale-down & scale-up vision is very useful in enabling us to improve the production yield of our yeast and bacteria host-based processes.

In conclusion, the addition of Y. lipolytica to our capabilities portfolio certainly matches with the growing trend for using yeasts to produce a broad spectrum of proteins.