Biocatalysts Ltd expands its Manufacturing Capabilities with Large-Scale Freeze Drying

This latest investment in large-scale freeze-drying onsite, enables greater customisation of solutions, tailoring enzyme formulations specific to customer and industry needs to offer flexibility and precision in enzyme formulation.

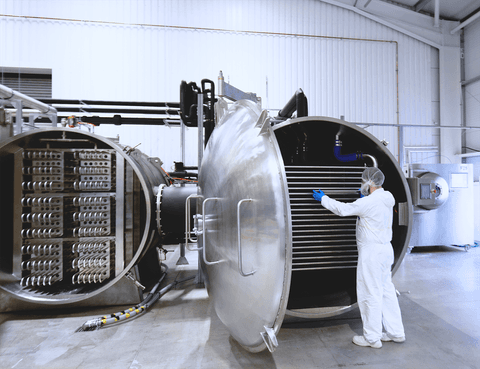

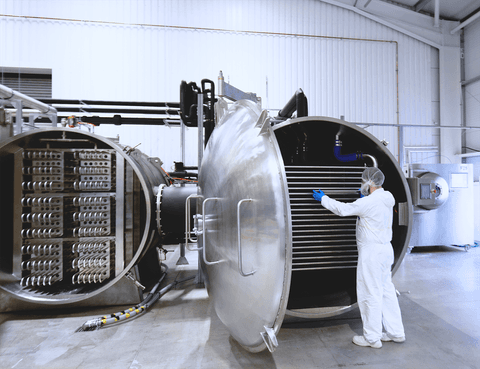

Biocatalysts Ltd, a leading expert in enzyme discovery, development and fermentation for the Food, Beverage and Life Science industries today announced a significant expansion of its manufacturing capabilities with the addition of large-scale freeze-drying equipment at its Cardiff manufacturing site.

Life sciences and biotechnology industries extensively use freeze-drying to preserve and protect products from loss of functional and biological activity. To meet stringent customer requirements and to ensure optimal product quality, the new industrial scale freeze-drying capacity was designed to align with both kosher and halal requirements and compliance with ISO9001:2015 and FSSC22000 quality and safety standards.

The current expansion fits into Biocatalysts’ multi-year manufacturing expansion program to accommodate increased demand for fermentation capacity and enzyme products. Other expansions have included investments in fermentation vessels, downstream processing, and formulation capacity. This latest investment in large-scale freeze-drying onsite, enables greater customisation of solutions, tailoring enzyme formulations specific to customer and industry needs to offer flexibility and precision in enzyme formulation.

“Freeze drying is a very sensitive approach for drying specialist products allowing for preservation of valuable functionality in the dried product. Our new custom-designed freeze drier provides large capacity and extremely efficient drying of our products. The drier is designed for maximum flexibility to meet the needs of a wide range of custom-dried products. This is an extremely valuable addition to our manufacturing capabilities at Biocatalysts Ltd