Fermentation Services

Modern biotechnology opens avenues to expand the use of microorganisms on an unprecedented scale to help build sustainable systems for healthy food production and scalable industrial biocatalysts.

Fermentation Services at Biocatalysts

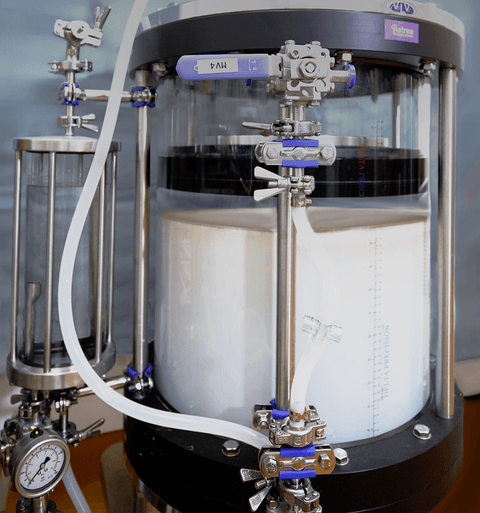

Our Enzyme Development Suite hosts a range of micro-fermentation technology at 0.5L and 3L fermenter volumes with dedicated scale down-stream processing development at laboratory scale. This suite enables our Team to fully optimise fermentation processes prior to transferring to larger volumes.

Your protein of interest and process can be seamlessly scaled up to 70L fermentation volume to confirm optimised fermentation conditions. The output from this phase is a fully scalable, optimised enzyme production process primed for production at commercial volumes.

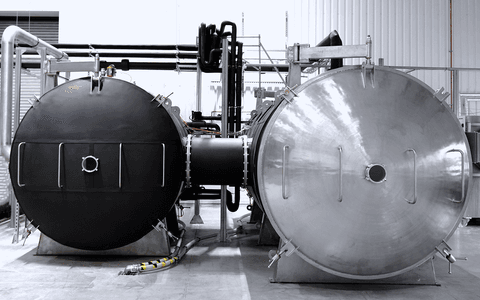

As part of our manufacturing process the protein will go through an appropriate pilot scale up to 750L. We have industrial scale fermentation capacity of 2 x 10,000L and full downstream processing including, centrifugation, ultrafiltration, bactofiltration, chromatography, spray- and freeze drying capabilities. Onward capabilities to larger commercial scales of up to 63,000L can also be achieved.

'Plug & Produce'

bringing product to market quicker

enhancing reliability and strengthening your supply chain

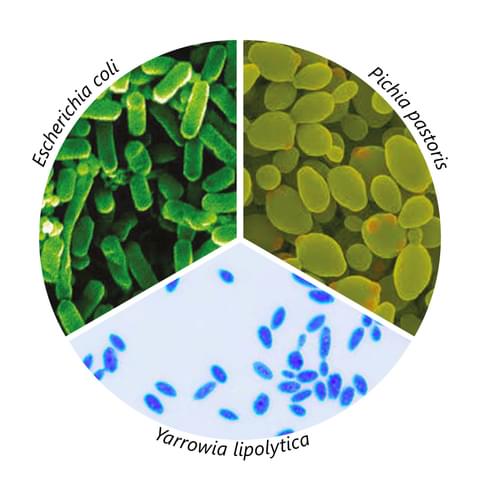

Developing enzyme and protein fermentation processes can be long and expensive and is often reliant on a single partner. “Plug & Produce” can bring product to market quicker and allow companies to efficiently develop a reliable production platform. With experience of over 190 scale-up projects, Biocatalysts Ltd. developed the “Plug & Produce” platform to optimise yields and performance in manufacturing enzymes. The platform offers bacteria, fungi as well as yeast hosts. These hosts have been developed in collaboration with Biocatalysts Ltd.’s parent company, BRAIN Biotech, who excel in enzyme discovery, engineering and host construction.

Microorganism Strain Development & Optimisation

Fermentation as a scalable technology starts with the microorganism hosts that act as factories in which cells are capable of producing very precise ingredients through very rapid duplication. Fermenting proteins requires the synergy between protein of interest and microorganism strain. Different proteins, and even different classes of enzymes are known to be better suited to specific microorganisms. To achieve optimum fermentation expression of the protein, genetic engineering or evolutionary optimisation methods at BRAIN Biotech can be explored to best reach target strain productivity. For more information on BRAIN Biotech's discovery, development and optimisation of microbial strains, click below.